Compact Coil feed lines for stamping presses

- Packaging:

- Woodencase

- Productivity:

- 100 sets

- Brand:

- Mayflay

- Transportation:

- Ocean,Land,Air

- Place of Origin:

- China

- Supply Ability:

- 100 sets

- Certificate:

- CE

- HS Code:

- 84283920.00

- Port:

- Shenzhen

Basic Info

Model No.: MAC4

Product Description

| Product Description |

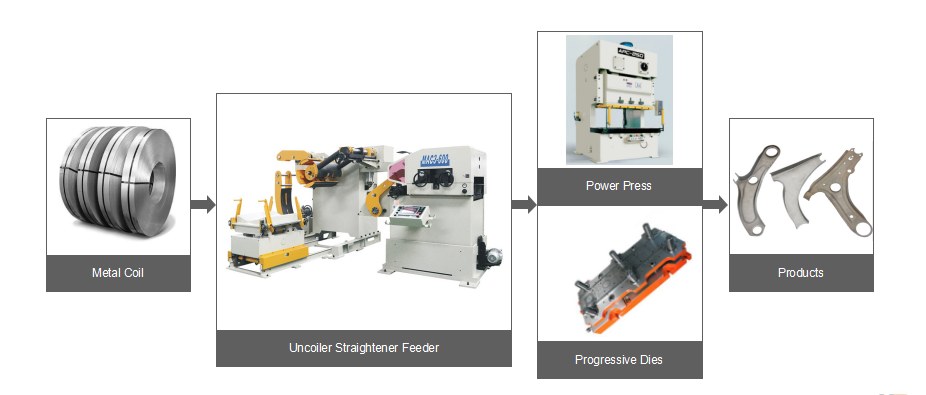

Compact Coil feed lines for stamping presses in the short space design were especially developed to meet the needs of customers. The particularly Compact Coil feed lines for stamping presses is made up of two main units: the feeder-straightener and the motorized uncoiler and an optional coil-loading car all mounted in a space saving footprint.Both machines rest on an arc-welded connecting base.

The feeder-straightener is connected to the press by means of output bracket with sliding guides which allow the sheet metal to be vertically aligned to the stamping die, at the same time as maintaining its horizontal rigidity.

The uncoiler is made up of arc-welded steel structure which supports the four spoked, hydraulic expanding mandrel. The mandrel is driven by a hydraulic motor which is coupled to a pneumatic disc brake.

The uncoiler can be equipped with a hydraulic snubber roll with hydraulic motorised wheel and the feeder-straightener can be fitted with a oil-pressure telescopic intake with upper counter-roller. Sheet metal of greater thickness can be fed into the die with these two alternatives, without the assistance on the part of the operator, who follows the entire tooling operation from the electrical panel. The sheet metal can be moved and centred inside the die by the operator by means of a portable push-button panel which is particularly useful when working with very large presses.

The entire line is cordoned off on two sides by barriers and photoelectronic barriers can be installed on the operators side on request. Any feeder model can be matched to the width and the capacity of the reel thereby obtaining various customized combinations.

They offer process reliability even for the most demanding materials. Compact Coil feed lines for stamping presses are optimally suited for the manufacture of structural parts as well as for processing of high-strength materials.Even for the higher ranges of strip thickness. In addition, they are the ideal solution for use in plants with limited space availability. Our product program includes coil lines in high-performance basic models that are adapted to all press types.

Compact Coil feed lines for stamping presses Model:MAC4 Model MAC4-400 MAC4-600 MAC4-800 MAC4-1000 MAC4-1300 Stock Width(mm) 70~400 70~600 70~800 70~1000 70~1300 Stock Thickness(mm) 0.6~6.0 0.6~6.0 0.6~6.0 0.6~6.0 0.6~6.0 Max.Coil Weight(kg) 5000 5000 7000 7000 7000 Max.Coil O.D.(mm) 1400 1400 1400 1400 1400 Coil I.D.(mm) 508 508 508 508 508 Feed Length(mm) ~500* ~500* ~500* ~500* ~500* Max.Line Speed(m/min) 16~24 16~24 16~24 16~24 16~24 Straightener Rolls(piece) upper 4/down 3 Feed Rolls (set) 1 1 1 1 1 Main Motor AC5.5 AC7.5 AC7.5 AC11.0 AC11.0 Mandrel Expansion Hydrauilc Hydrauilc Hydrauilc Hydrauilc Hydrauilc Reel Motor(kw) 2.2 2.2 3.7 3.7 3.7 Power(v) 3 Phase 220V/380V/50HZ Operating Air(Mpa) 0.49 0.49 0.49 0.49 0.49

Straightening Performance Material Tech-info of thickness & Width MAC4-400 MAC4-600 MAC4-800 MAC4-1000 MAC4-1300 0.6~1.3 400 600 800 1000 1300 2 2.3 2.5 1170 2.8 933 933 3.2 714 714 714 4 457 457 457 457 4.5 361 361 361 361 361 5 293 293 293 293 293 6 203 203 203 203 203

Remarks:

1)The above figures are the material having yield strength σs=245N/mm² ,Max. tensile strength σb=392 N/mm²)

2)Specifications are subject to change for improvement without notice.

Products Show

The Main Detailed Parts of Compact Coil feed lines for stamping presses as below:

1. Coil Car---Hydraulic power, wear-resisting surface2. Decoiler Mandrel ---Hydraulic Expansion, Delta Inverter

3. Pressing Arm---Coil well-knit, no disperse

4. Limiting Arm--- Locating coil, avoid coil shuffling

5. Support Arm---Auxiliary support coil

6. Coil Inlet---With supporting swing arm

7. Control Cabinet---Weinview Touchscreen

8. Straightening Part---GCr15 steel straightener rolls

9. Handwheel --- Straightening value adjustment

10. Shearing Unit---Hydraulic shear (Optional)

11. Lubrication Unit---Automatic control, 20L (Optional)

12. Outlet Bracket --- Adjustable length

| Application |

Automobile stamping, appliances manufacturing, computer and electronic componets, hardware and metal parts etc industry.

Automotive Parts: Bracket, Damper, Barke Pad, Tie Bar, Electric Accessory, Shell Parts Of Printers, Computer Frame,Slide Rail of Car Seat, Splash Shield of car body and etc

MAC4 Compact Coil feed lines for stamping presses is working in our customer's factory.

Compact Coil feed lines for stamping presses for making the bracket coil sheet feed line.

This machine is workinng in one of our customer's factory, they produce U type parts with Compact Coil feed lines for stamping presses.

With the Yaskawa Servo Systems and Mitsubishi PLC control, the feeding line can reach ±0.15mm feeding accuray.

Product Categories : Decoiler Straightener Feeder > Compact Feed Lines