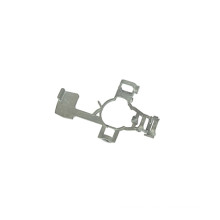

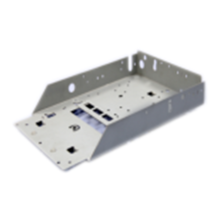

Aluminium Cover

Product Description

Applicable Industry: Auto parts, motor shell, pump parts, machinery parts,lamp chimney.

Die Casting process description:

Die casting is the process where molten metal is injected into a mold

under high pressure in the range of 10 210 Mpa. This will result in a

highly uniform casting with very good surface finish and exceptional

dimensional accuracy. Usually this can either eliminate or greatly

reduce the machining required to finish the part.

We can offer both the cold chamber process and the hot chamber process.

In the cold chamber process the metal is ladled into the injection

chamber for each shot. There is less exposure of the molten metal to the

chamber walls and plunger. This is very useful for aluminum and copper

alloys that would easily alloy with iron at elevated temperatures. The

hot chamber process has the injection chamber which is connected to the

die cavity permanently immersed in the molten metal. The hot chamber

process is used for metals of low melting point and high fluidity such

as tin and zinc.

We produce a wide range of Aluminum Die Casting and other alloys, form

simple to complex designs. Please send us drawings or samples, we can

make all kinds of OEM parts for you. Contact us if you need more details on Aluminium Die Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum Die Casting、China Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Die Casting process description:

Die casting is the process where molten metal is injected into a mold

under high pressure in the range of 10 210 Mpa. This will result in a

highly uniform casting with very good surface finish and exceptional

dimensional accuracy. Usually this can either eliminate or greatly

reduce the machining required to finish the part.

We can offer both the cold chamber process and the hot chamber process.

In the cold chamber process the metal is ladled into the injection

chamber for each shot. There is less exposure of the molten metal to the

chamber walls and plunger. This is very useful for aluminum and copper

alloys that would easily alloy with iron at elevated temperatures. The

hot chamber process has the injection chamber which is connected to the

die cavity permanently immersed in the molten metal. The hot chamber

process is used for metals of low melting point and high fluidity such

as tin and zinc.

We produce a wide range of Aluminum Die Casting and other alloys, form

simple to complex designs. Please send us drawings or samples, we can

make all kinds of OEM parts for you. Contact us if you need more details on Aluminium Die Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum Die Casting、China Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Die Casting with Surface Treatment > Die Casting with Electroplating

Premium Related Products

Other Products

Hot Products

die for round pipe cylinder honing head motor casingcustomized die casting power coating lamp shadescustomized zinc alloy die casting decoration manufacturercustomized die casting door holdercustomized moldes zinc alloy mental zipper slider moldcustomized motorcycle parts names of motorcycle engine partscustomized die casting automatic washing machines spare partsAluminium Die CastingMetal precision die castingAluminium Die CastingAluminium Die CastingAluminium Die CastingAluminium Die CastingAluminium CoverLed Lighting Cover L025Led Lighting Gasket